Used oil

Summary

The presence of used oil storage tanks at Small Craft Harbours (SCH) sites represents an environmental risk. Releases of petroleum products related to used oil storage tanks, such as spills due to overfilling, may cause environmental problems. This includes soil, groundwater, and surface water contamination. These releases may also pose fire and other human health hazards. As such, the management of used oil storage tanks should be carefully monitored.

The purpose of the used oil tools is to provide Harbour Authorities (HAs) with access to information related to the management of used oil storage tanks in an effort to help improve used oil management at SCH and to further reduce the risk of environmental contamination.

On this page

- Summary

- Emergency

- First Aid Measures

- Emergency Response Equipment

- Environmental Emergency Response Plan (EERP)

- Operational

- Federal regulations

- Roles and responsibility

- Used oil pick up

- Training

- Equipment

- New installation and removal

- Removal Requirements

- Used Oil Tank Building

- Housekeeping and Maintenance

- Signage

- Useful links and downloads

- Frequently Asked Questions

Emergency

According to Environment and Climate Change Canada; 'an environmental emergency is an uncontrolled or unexpected incident involving the actual or likely release of a polluting substance into the environment'. This makes used oil tanks an environmental risk since they can be a source of release of a polluting substance into the environment.

It is important to be prepared in case of such events. This includes being aware of first aid measures concerning used oil, having the proper emergency equipment and developing a proper environmental emergency response plan (EERP).

A copy of the site-specific Emergency Contact List should be posted near the used oil tank or used oil storage area.

First aid measures

In the event of human exposure to used oil, the following first aid measures should be used:

- Inhalation - Move victim to fresh air. Give artificial respiration if breathing has stopped and if a qualified Artificial Respiration administrator is available. Apply CPR if pulse and breathing have stopped. Obtain medical attention immediately

- Ingestion - Never give anything by mouth if the person is unconscious, rapidly losing consciousness or convulsing. If the person is conscious, provide 1 glass of water or milk to dilute the material in the stomach. Do not induce vomiting. If vomiting occurs spontaneously, have the person lean forward to avoid aspiration. Obtain medical attention immediately

- Eye contact - If irritation occurs, flush eye with lukewarm, gently-flowing fresh water for at least 15 minutes. Obtain medical attention immediately

- Skin contact - Quickly and gently blot away excess oil. Gently remove contaminated clothing and shoes under running water. Wash gently and thoroughly with water and nonabrasive soap. Obtain medical attention

Emergency response equipment

The minimum emergency response equipment at a used oil storage tank should consist of a fully stocked spill kit and a fully charged type ABC fire extinguisher.

As a minimum, each spill kit should contain:

- Yellow caution tape

- Absorbent/containment booms

- Absorbent "Loose Particulate"

- Oil-only absorbent pads

- Disposal bags and ties

- Overpack drum

- Disposable coveralls C/W, gloves, safety glasses/goggles

- Instruction sheet for how to clean up an oil spill affixed to the underside of the screw top (French and English)

For additional information related to the procurement/replenishment of spill kits items, please contact your regional SCH representative.

Environmental emergency response plan (EERP)

All Harbour Authorities should have an EERP in place as it is legally required for petroleum storage tank systems regulated under the Canadian Environmental Protection Act (CEPA) Storage Tank Systems for Petroleum Products and Allied Products Regulation, SOR/2008-197. Even for storage tank systems that are not regulated, it is the responsibility of every HAs to have an EERP in place, according to the lease.

The purpose of an EERP is to eliminate, reduce, and/or mitigate the health, safety, and environmental impact of an uncontrolled, unplanned, or accidental release of used oil into the environment, as a means of meeting regulatory requirements. The 5 elements of this approach are prevention, preparedness, response, recovery, and reporting.

- Prevention – actions which eliminate or reduce the probability of an environmental emergency associated with the used oil storage tank system at the harbour

- Preparedness – measures taken before an emergency to ensure an effective response

- Response – actions taken to respond to an actual emergency. These actions are aimed at providing a controlled, effective, and timely response.

- Recovery – actions taken to recover from an emergency that could be short-term or long-term activities. The aim is to return all systems and harbour activities to normal operation

- Reporting – protocols for notifying the appropriate agencies and the public, as required

The EERP is intended to provide the HA with a communication and operational protocol to follow during an environmental emergency. The EERP must be available close to the tank (e.g. inside the spill kit) and accessible to those required to carry out the Emergency Plan.

The following is an example/template of a site specific EERP related to used oil tanks. This EERP template can be downloaded by HAs and customized for each individual SCH.

For additional information related to EERPs, contact your Regional SCH representative.

Operational

SCH often provides used oil tanks to HA. In other instances, the used oil tanks are HA owned. The presence of these tanks promotes the proper collection, storage, and disposal of used oil. Tank capacities are typically in the range of 1,000 – 3,500 L, and the tank may be located either outside or within a building.

Federal regulations

Used oil tanks are regulated by Environment and Climate Change Canada (ECCC). This means they require specific signage, labels, inspections, and management to meet the Canadian Environmental Protection Act (CEPA) regulations. This is why it is important to be familiar with these expectations in case of future audits or inspections from these ECCC agents.

All petroleum storage tank systems located on SCH property must be installed and operated in accordance with the respective tank manufacturer's specifications and must comply with the applicable provisions of the following applicable regulations and codes for used oil tanks. Additional information related to these codes and regulations are located below the table.

| System Aggregate Capacity | Applicable Regulation or Code | ||

|---|---|---|---|

| Federal Regulation (CEPA Regulation) | National Fire Code | CCME Code of Practice | |

| Used oil system >230 L (without secondary containment) | |||

| Used oil systems located in a building that provides secondary containment | |||

Federal regulation (CEPA regulation)

The storage of used oil in an aboveground storage tank in a fixed location is regulated by the "Storage Tank Systems for Petroleum Products and Allied Petroleum Products Regulations, SOR/2008-197" under the Canadian Environmental Protection Act (CEPA). Any used oil storage tank greater than 230L must be registered under the Regulations.

The main objective of these CEPA regulations are to prevent soil and groundwater contamination from petroleum storage tank systems located on federal and aboriginal lands.

As required by the Storage Tank Systems for Petroleum Products and Allied Petroleum Products Regulations, all registered tanks must have an Environment and Climate Change Canada (ECCC) identification number affixed on the tank in a visible location. A registered tank system is typically located on a concrete pad outside.

Non-registered systems are storage tank systems that are set inside a building that includes a secondary containment floor pan meeting specific requirements that excludes them from being regulated by CEPA, and also do not require an ECCC identification number. This also applies to tanks that are 2500L or less and the systems are connected to a heating appliance or emergency generator.

More information on these regulations are available at Overview of the storage tank regulations - Canada.ca

National Fire Code of Canada

This Code identifies requirements for storage and handling, use, and processing of flammable liquids and combustible liquids in buildings, structures, and open areas. Part 4 of the Code specifically addresses the storage, handling, use, and processing of flammable and combustible liquids in buildings, structures, and open areas. More information related to the NFC can be found at: https://nrc-publications.canada.ca/eng/view/object/?id=cd32b653-318c-441a-bacd-08bd39332275

Environmental code of practice for aboveground and underground storage tank systems containing petroleum and allied petroleum products (CCME)

This Code of Practice presents the minimum requirements for existing, new or proposed aboveground and underground storage tank systems that contain petroleum products and allied petroleum products. The purpose of the Code of Practice is the promotion of environmentally sound management of storage tank systems. This is done through the application of uniform performance standards throughout Canada.

Roles and responsibility

Harbour authorities have the responsibility to:

- Develop rules and policies surrounding the management of used oil

- Adopt these rules & policies

- Clearly and effectively communicate the harbour rules and applicable policies to users

- Consistently and without bias enforce the rule and applicable policies and explain why they exist

- Ensure that a copy of the EERP is provided at the waste oil tank site

- Ensure that system users, site personnel, and contractors are aware of the EERP, its location, and the location and usage of emergency response equipment

- Ensure that contact information is up to date and posted near the used oil storage tank system

- Ensure that local emergency responders are contacted in the event of an emergency

- Ensure that SCH is advised when the on-site emergency response equipment needs replacement

- Ensure that if warranted by emergency, personnel in the vicinity are notified, with respect to the emergency

- Undertakes and documents monthly visual inspection of the used oil tank system and reports deficiencies to SCH

SCH has the responsibility to:

- Provide the tools and guidance to the Harbour Authority for the management of used oil tanks

- Ensure that the EERP is in place and up to date

- Ensure that the Emergency response equipment (e.g. spill kit) is available at the site

- Ensure that the personnel who operate, inspect, and maintain the waste oil storage tank system are familiarized with the EERP and the location and usage of emergency response equipment

Harbour users have the responsibility to:

- Become familiar with the EERP

- Become familiar with the location and usage of the emergency response equipment

- Advise Harbour Authority when emergency response equipment needs replacement

- Follow posted signage and user rules, and keep the used oil area clean, tidy and accessible

As a general guidance, these rules should be followed by the storage tank managers:

- Signs with concise instructions regarding where to dispose and how to dispose of used oil must be clearly displayed at the used oil station

- Mixing unsuitable products such as gasoline, antifreeze, solvents, cooking oil, bilge, water, etc. with used oil must be prevented. Mixing used oil with such products can significantly increase the cost of disposal

- Used filters, oily rags and debris must be stored in ULC approved well labeled containers and removed from site on a regular basis. A space must be designated for these containers (inside the used oil building if possible)

- The site must be kept clean and easily accessible at all times

HAs could appoint a volunteer or a summer student to conduct daily housekeeping and checking the used oil tank on a regular basis. This person could be shared between multiple harbours when appropriate, and could also provide positive feedback/reinforcement to harbour users relating to the proper use of the used oil system.

In case of repetitive problematic behavior, a surveillance camera could be installed. Once the individuals have been identified, adequate training and awareness sessions can then be provided.

Used oil pick up

The used oil tank is ready to be emptied when the used oil tank is nearing ¾ of its capacity. Used oil must be collected and disposed of in a manner acceptable to the provincial environmental department or agency having jurisdiction. This may include using a provincially approved hauler or collector. The following table includes approved used oil collection agencies, by province.

| Province | Name of organization | Website | Contact Information |

|---|---|---|---|

| British Columbia | Used Oil Management Association (BCUOMA) | https://bcusedoil.com/ | Phone: 778-817-0721, (Toll Free): 1-844-722-8662 |

| Alberta | Alberta Recycling Management Authority (Alberta Recycling) | https://www.albertarecycling.ca/ | 780.990.1111, toll free 1.888.999.8762 |

| Saskatchewan | Association for Resource Recovery Corp (SARRC) | http://usedoilrecyclingsk.com/ | 1-877-645-7275 |

| Manitoba | Association for Resource Recovery Corp (MARRC) | http://usedoilrecycling.com/en/mb/node/1 | 1-888-410-1440 |

| Quebec | La Societe de gestion des huiles usagee (SOGHU) | https://soghu.com/en/homepage | 1.877.987.6448 |

| New Brunswick | Atlantic Used Oil Management Association (UOMA NB) | https://nb.uoma-atlantic.com/en/homepage | 1‑833‑221‑8662 |

| Pince Edward Island | Atlantic Used Oil Management Association (UOMA PE) | https://pe.uoma-atlantic.com/en/homepage | 1‑833‑221‑8662 |

| Nova Scotia | Atlantic Used Oil Management Association (UOMA NS) | https://ns.uoma-atlantic.com/en/homepage | 1‑833‑221‑8662 |

| Newfoundland | Atlantic Used Oil Management Association (UOMA NL) | https://nl.uoma-atlantic.com/en/homepage | 1‑833‑221‑8662 |

* It is to be noted that Ontario does not have an official collection organization for used oil. If more information is needed for used oil pick up in Ontario, please contact your SCH representative.

Training

To be effective in managing environmental issues related to used oil systems, HA personnel may require specialized training to minimize risks to other staff and harbour users.

Training can include topics such as the proper handling and disposal of used oil products, risks associated with improper handling of these products, and EERP application. Formal training is typically offered by SCH and/or the Office of Environmental Coordination (OEC) related to these issues, at the discretion of SCH/OEC. However, training is often given on a rotation schedule of 3 years, which means that new HA personnel may not receive the required training in a timely manner.

Equipment

Used oil storage tanks are used at SCH sites to store used oil. The tanks are provided by SCH to harbour users at many facilities as a harbour amenity and their presence promotes the proper storage and disposal of used oil. Used oil tanks may be located outside or inside a purpose-built building.

New installation and removal

New storage tank installations must meet certain sections of the Canadian Council of Ministers of the Environment (CCME) Environmental Code of Practice for Aboveground and Underground Storage Tank Systems Containing Petroleum and Allied Petroleum Products. Also, they must conform to certain industry standards (i.e. the appropriate ULC tank design standard for a given application). Refer to Section 3.5 Aboveground Storage Tank Systems for Storing Used Oil on the CCME Environmental Code of Practice for information of the applicable design standard for used oil tanks.

New system installation requirements

- Contact a provincially approved licensed petroleum contractor or Engineering firm

- Submit the SCH application forms including design drawings to SCH RHQ

- Plans and specifications must bear the stamp and signature of a Professional Engineer

- The installation contractor must prepare as-built drawings

- SCH RHQ will review the application including design drawings for approval prior to installation

- Obtain an new ECCC Identification number prior to tank construction and install on tank

- SCH RHQ will complete a final inspection following installation

- Prepare a new EERP for the new used oil tank (if 1 does not already exist) and post it near the used oil tank. Site-specific environmental emergency response plan template (with tank).

Used oil tank systems must be located away from vehicle traffic and protected from impacts by vehicles, trailers, forklifts, etc.. Tank systems must not be placed closer than 4.5m horizontally from the normal annual high-water mark . Tank systems should not be placed on a wharf or on an approach to a wharf without approval from the SCH Regional Engineer and these systems must not exceed 5,000 L in capacity .

Removal requirements

A provincially approved installer must conduct a tank system removal. If none exists, a professional engineer must supervise the removal.

- Notify SCH of planned used oil tank removal to ensure risks are mitigated

- Removal of used oil tank by contractor and disposal of used oil tank at an approved disposal site

- Obtain a disposal slip from contractor

- Once removed, notify ECCC (within 60 days)

The table below provides a list of provinces and territories with approved installers.

| Province / Territory | Certified Installer contractors? | Certified removal contractors? |

|---|---|---|

| British Columbia | No | No |

| Alberta | Yes | Yes |

| Saskatchewan | Yes | Yes |

| Manitoba | Yes | Yes |

| Ontario | Yes | Yes |

| Quebec | Yes | Yes |

| New Brunswick | Yes | Yes |

| Nova Scotia | Yes | Yes |

| PEI | Yes | Yes |

| Newfoundland | No, except home heating oil inspectors | No |

| Yukon | No | No |

| NWT | No | No |

| Nunavut | No | No |

Used oil tank building

The location of used oil tanks is very important both to avoid spills occurring in a sensitive environment and to protect the tank from accidents. A great way to decrease the risk of an environmental spill related to a used oil tank is to have it installed inside a purpose-built building with proper ventilation and built-in containment (see photo below). Tanks that are enclosed in a building are protected against unauthorized use and extends the service life of the tank. The enclosure also protects the tank area from rainwater infiltration and helps to reduce the possibility of waste oil being carried off by storm water runoff. Another advantage is that the enclosed area provides a protected space to locate a spill kit and disposal bins for oily rags and used oil filters. If the building has been designed to fully contain spills or leakage from entering the environment, the tank may be exempt from the CEPA regulations; however, SCH approval is still required.

Examples of SCH used oil tank buildings:

For more Information on these types of installations, please contact your local SCH agent.

Housekeeping and maintenance

To reduce the risk of a spill or leak related to used oil tanks, proper housekeeping etiquette and regular maintenance are encouraged.

Tank:

- Perform operational visual inspections and take corrective action. For single-walled tanks without secondary containment, these inspections are required monthly and the records must be kept for 5 years

- Regularly remove oil filters, rags and other debris for proper disposal

- Ensure the tank fill area is in good repair and tidy as required

- The screen box should be kept clean and free of debris

- Check the tank vacuum gauge (double-walled tanks so equipped) and arrange for service if pressure is low or zero (i.e., same as atmospheric pressure)

- Ensure the Environment Canada ID number is visible on the tank (unless the tank is exempt from federal regulations because the tank is in an SCH approved secondary containment building)

- Check tank fill level and inform Harbour Manager or call for disposal when ¾ full

- Paint the tanks as required with SCH approved marine paints

Surrounding area:

- Ensure the vegetation around the tank is trimmed, being careful not to scuff the paint or damage the tank

- The area surrounding and under the used oil tank should be clean and free of debris

- Empty any full buckets into the tank carefully

- Ensure required signage is posted

- Paint traffic bollards as required with approved brightly-coloured marine paints

- Post and enforce 'no parking' in the immediate area

- Maintain a properly stocked spill kit

- Post the EERP in a weather-proof container

Tank enclosure/building (if applicable):

- Keep the enclosure area tidy

- Inspect enclosure floors for spilled used oil and clean up any spilled material

- Ensure tank is properly vented to the outside (if fully enclosed building)

Used oil filters, oily rags, and debris:

- These items must be stored in separate ULC approved containers and removed from the site regularly by designated waste handlers

- Harbour Authorities should designate a space for these containers on site (either near the waste oil tank or inside the waste oil building)

- Clearly label the containers

Camera or video surveillance

Harbours with housekeeping concerns (i.e. open waste oil pails left by the waste oil tanks) could consider the installation of a high-resolution camera or video surveillance camera near the waste oil tank. This method has proven to be successful at some SCH harbours. The presence of a camera will encourage good housekeeping practices for harbour users. This can help with reducing the potential for spills. It may also protect from unauthorized use (i.e. deter non-harbour users from disposing waste oil at the site). Once the individuals have been identified, adequate training and awareness sessions can then be provided. Video cameras can be purchased at retail stores or online retailers with varying price points.

Amalgamate tanks

Waste oil tanks could be removed from problematic harbours and relocated at centralized harbours where waste oil management is good. This solution should only be considered if the environmental risk of the waste oil tank outweighs the benefits of having the waste oil tank onsite and if the HA and SCH have both agreed that it is the only solution.

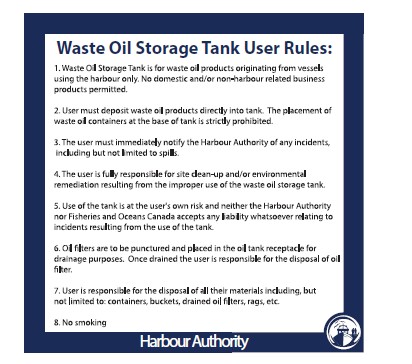

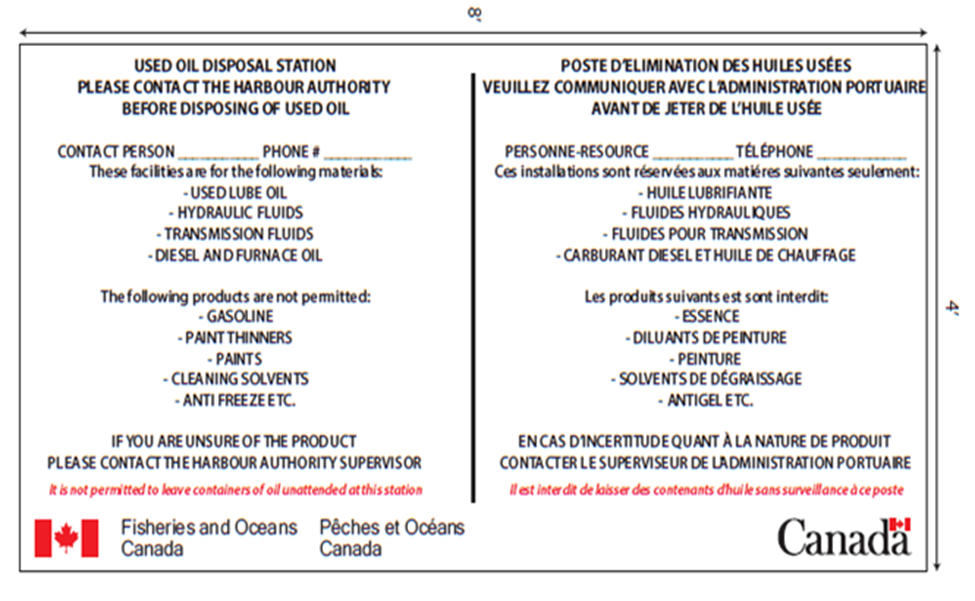

Signage

The presence of signage near the used oil station will help promote environmental awareness and will help identify best practices to be used while using the waste oil system. Unless otherwise specified by regional requirements, SCH suggests the following signage be present at SCH used oil facilities:

- Rules for used oil handling including who to contact when the tank is nearing its capacity and the cost implications of mixing unsuitable products

- Location of the emergency plan and the emergency telephone number

- A WHMIS warning and product identification label printed in both official languages

- No smoking labels in both official languages and meeting NFC standards

- A label indicating that moving the tank without SCH approval is prohibited

Below are other suggestions of signage that can be installed near the used oil facilities:

- Standard Operating Procedure for the used oil tank – include clear step by step process on how to properly dispose of used oil in the used oil tank

- risks of improper use, contamination, and consequences if improper use continues

- Products that can and cannot be disposed into the used oil tank

- Disposal options for products that cannot be disposed in the used oil tank (i.e. antifreeze, paint, etc). This list will vary by province

Examples of signs:

Signage Disclaimer: While effective signage will help ensure the safe appropriate use of the used oil station, it does not replace the need for those responsible for the harbour to conduct regular visual inspections of the waste oil tank and surrounding area, or undertake other acts of due diligence.

For more information on signage, please contact your local SCH manager

Useful links and downloads

- CCME Environmental Code of Practice

- Storage Tank Systems for Petroleum Products and Allied Petroleum Products Regulations (SOR/2008-197)

- Site-specific environmental emergency response plan template (with tank)

Frequently Asked Questions

1. What are the environmental impacts related to used oil tanks?

Leaks related to waste oil tanks can have devastating environmental and economic impacts. Small quantities of waste oil can cause offensive odours, contaminate surface and subsurface soils, render drinking water from aquifers non-potable. Petroleum hydrocarbon spills continue to represent a significant liability to the federal house.

2. What are a Storage Tank Site Operator's responsibilities under the Department's National Petroleum Storage Tank System Environmental Management Plan?

The Storage Tank Site Operator is responsible for the day-to-day operations of a storage tank system. They supervise product delivery; conduct inspections and routine maintenance; and inform the operator and owner (and others as required) in writing when a leak is suspected or a spill occurs. The Storage Tank Site Operator must follow the procedures designed specifically for each type of tank system on time, in addition to completing forms or logs as required (ex. print name, sign and date). The Storage Tank Operator or the DFO Regional Offices of Environmental Coordination can advise on these requirements.

3. When should a used oil tank be replaced?

The tank should be replaced every 10 years.

4. How can I tell that the used oil tank is almost full?

The tank should have a tank level gauge indicating the level of used oil in the tank. If no gauge is present on the tank, 1 should be installed.

5. When/how often should the used oil tank be emptied?

When the tank is ¾ full, a provincially certified disposal contractor should be contacted to empty the tank.

6. Why is it important to recycle used oil?

By recycling used oil, you are making sure that the oil is reused in a proper manner. This includes re-refining lubrication oil, industrial burner fuel or even other products. Therefore, a proper used oil management program makes sure that the oil does not end up in an unwanted environment.

- Date modified: